Last Updated on July 27, 2023

Welcome to our article on how to bake a GC column. If you’re a high school student in years 10-11 or someone new to gas chromatography, this guide will provide you with a comprehensive understanding of the process. A GC column is a crucial component in gas chromatography, responsible for separating and analyzing different compounds in a sample. In this article, we will walk you through the steps of preparing, baking, cooling, and testing a GC column. We will also provide troubleshooting tips and advice on maintaining a baked GC column. So, let’s dive in and explore the fascinating world of GC column baking!

Understanding the GC Column

The GC column is a crucial component in gas chromatography, as it is responsible for separating and analyzing the different components of a sample. Understanding the GC column is essential for achieving accurate and reliable results. Here are some key points to consider:

- The GC column is a long, narrow tube made of a stationary phase coated on the inside.

- The stationary phase is typically a high-purity liquid or solid material that interacts with the sample components.

- The length and diameter of the GC column can vary, depending on the specific analysis requirements.

- The stationary phase is chosen based on the sample’s properties and the desired separation.

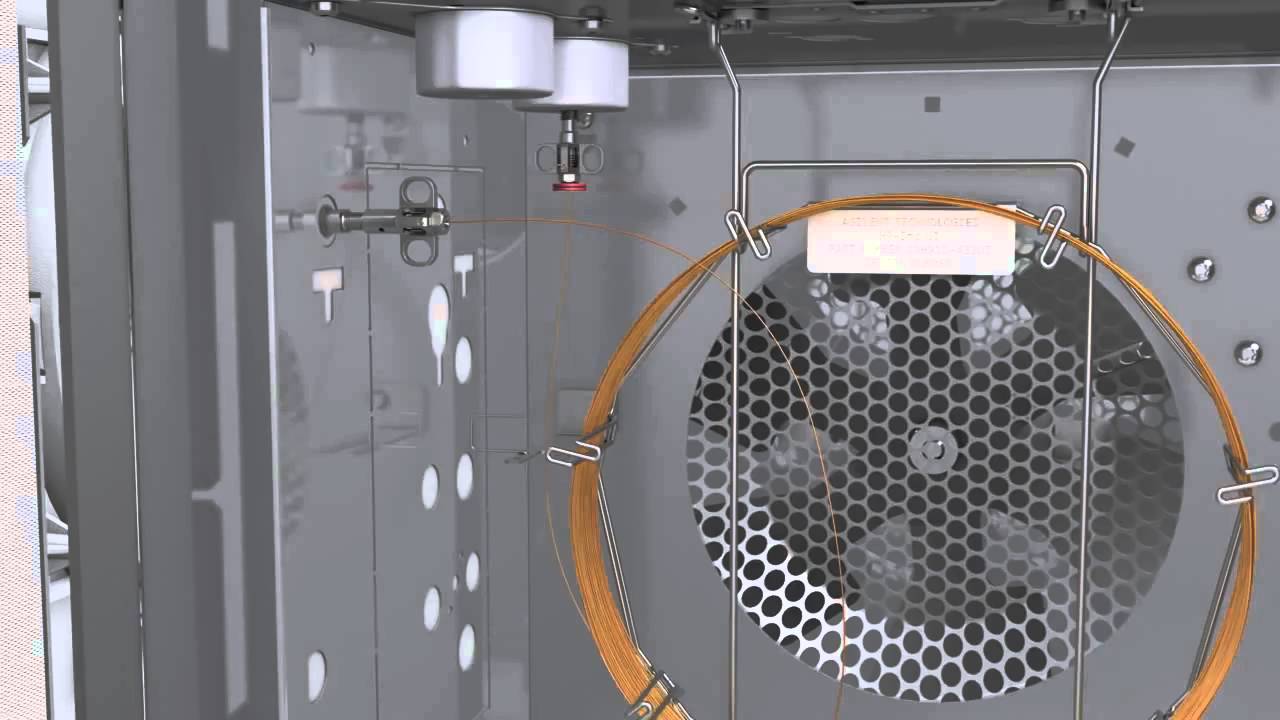

- The GC column is housed in an oven, which allows for precise temperature control during the analysis.

Having a good understanding of the GC column and its role in gas chromatography is essential for successful analysis. It is important to properly prepare and maintain the GC column to ensure accurate and reliable results.

Preparing the GC Column for Baking

Before you can begin the baking process, it is crucial to properly prepare the GC column. This involves several important steps to ensure optimal results.

First, you will need to remove the column from the gas chromatograph. This can be done by carefully disconnecting the column from the injector and detector.

Next, you will need to clean the column thoroughly. This can be done by flushing the column with a suitable solvent, such as methanol or acetone. This will help remove any residual contaminants that may be present on the column.

Once the column is clean, it is important to inspect it for any signs of damage or degradation. Look for any visible cracks or discoloration, as these can indicate that the column needs to be replaced.

Finally, you will need to trim the ends of the column. This can be done using a sharp pair of scissors or a column cutter. Trimming the ends will help ensure a clean and proper seal when the column is reinstalled in the gas chromatograph.

By following these steps, you can ensure that your GC column is properly prepared for the baking process, which is essential for optimal performance and accurate results.

Setting up the Baking Equipment

Before you can start baking your GC column, you need to make sure that you have all the necessary equipment set up and ready to go. Here are the steps to follow:

- Choose a suitable oven: You will need an oven that can reach high temperatures, typically around 300-400 degrees Celsius. Make sure the oven is clean and free from any residue that could contaminate the column.

- Prepare the oven: Set the oven to the desired temperature and allow it to preheat for at least 30 minutes. This will ensure that the oven is at a stable temperature before you place the column inside.

- Place the column in a suitable container: It is important to protect the column during the baking process. Place the column in a glass or metal container that can withstand high temperatures.

- Secure the column: Use clamps or other suitable methods to secure the column in place inside the container. This will prevent any movement or damage during the baking process.

- Position the container in the oven: Carefully place the container with the column inside the preheated oven. Make sure it is positioned in a way that allows for even heating.

Once you have set up the baking equipment, you are ready to move on to the next step: baking the GC column.

Baking the GC Column

– Baking the GC column is a crucial step in the preparation process, as it helps to remove any contaminants and improve the column’s performance.

– The baking process involves heating the column to a high temperature to remove any residual impurities and moisture.

– Here are the steps to follow when baking a GC column:

1. Prepare the column: Before baking, make sure to remove any fittings or connectors attached to the column. This will prevent any damage to these components during the baking process.

2. Set up the baking equipment: Place the column in a suitable oven or furnace that can reach the required temperature for baking. Ensure that the oven is clean and free from any debris that could contaminate the column.

3. Heat the column: Gradually increase the temperature of the oven to the recommended baking temperature. This temperature may vary depending on the type of column and the manufacturer’s instructions.

4. Bake the column: Once the oven reaches the desired temperature, keep the column in the oven for the recommended baking time. This time can range from a few hours to overnight, depending on the column’s condition.

5. Cool and condition the column: After baking, allow the column to cool down gradually to room temperature. This will prevent any thermal shock that could damage the column. Once cooled, condition the column by flushing it with a suitable carrier gas.

Baking the GC column is an essential step in maintaining the column’s performance and prolonging its lifespan. By following these steps, you can ensure that your column is properly baked and ready for analysis.

Cooling and Conditioning the GC Column

After baking the GC column, it is important to properly cool and condition it before use. This step ensures that the column is ready to provide accurate and reliable results. Here are the steps to cool and condition the GC column:

- Allow the column to cool down naturally: Once the baking process is complete, turn off the oven and let the column cool down naturally. Avoid any sudden temperature changes or exposure to extreme temperatures.

- Check the column temperature: Use a thermometer to check the temperature of the column. It should be at room temperature before proceeding to the next step.

- Condition the column: Conditioning the column involves removing any impurities or contaminants that may have accumulated during the baking process. This can be done by running a series of test injections with a known standard solution.

- Monitor the column performance: During the conditioning process, monitor the column performance by analyzing the test injections. Look for any signs of peak tailing, loss of resolution, or abnormal baseline noise.

- Repeat conditioning if necessary: If any issues are observed during the initial conditioning, repeat the process until the column performance meets the desired specifications.

By following these steps, you can ensure that your baked GC column is properly cooled and conditioned, ready for accurate and reliable analysis.

Testing the Baked GC Column

Once the GC column has been baked and cooled, it is important to test its performance before using it for analysis. Testing the column ensures that it is functioning properly and will provide accurate results.

One important test to perform is the baseline test. This involves running a blank sample through the column and observing the baseline on the chromatogram. The baseline should be flat and stable, indicating that there is no contamination or impurities present in the column.

Another test to consider is the peak shape test. This involves injecting a known standard compound and examining the resulting peak shape. The peak should be symmetrical and well-defined, indicating that the column is properly packed and has good efficiency.

It is also recommended to perform a retention time test. This involves injecting a mixture of known compounds and comparing their retention times to a reference chromatogram. The retention times should be consistent and match the reference, indicating that the column is properly calibrated.

By conducting these tests, any issues with the baked GC column can be identified and addressed before using it for analysis. This ensures accurate and reliable results in your gas chromatography experiments.

Troubleshooting Common Issues

When it comes to baking a GC column, there are a few common issues that can arise. Understanding how to troubleshoot these issues is essential for achieving optimal results. Here are some tips to help you overcome these challenges:

1. Uneven Baking

If you notice that your GC column is not baking evenly, it could be due to a few factors. First, make sure that the column is properly packed and there are no air pockets. Additionally, check the temperature settings on your oven to ensure they are accurate and consistent.

2. Column Breakage

Column breakage can occur during the baking process if the column is not handled with care. To prevent this, always use caution when removing the column from the oven and avoid any sudden movements or impacts. It is also important to properly secure the column in the oven to prevent it from shifting or falling.

3. Contamination

If you notice contamination in your GC column after baking, it could be due to improper cleaning or handling. Make sure to thoroughly clean the column before baking and avoid touching the stationary phase with bare hands. Additionally, ensure that all equipment and materials used in the baking process are clean and free from contaminants.

By addressing these common issues and following proper procedures, you can ensure that your baked GC column performs optimally and delivers accurate results.

Tips for Maintaining a Baked GC Column

Once you have successfully baked your GC column, it is important to maintain it properly to ensure optimal performance and longevity. Here are some tips to help you with the maintenance:

1. Store the column properly:

After baking, make sure to store the GC column in a clean and dry environment. Avoid exposing it to excessive heat or moisture, as this can degrade the column’s performance.

2. Regularly check for leaks:

Leaks can occur in the column connections or fittings, which can affect the accuracy and reproducibility of your analysis. Regularly inspect the column for any signs of leaks and fix them promptly.

3. Clean the column regularly:

Over time, contaminants can accumulate on the column, leading to decreased efficiency and increased baseline noise. Clean the column regularly using appropriate cleaning solutions to maintain its performance.

4. Replace the septum regularly:

The septum is a critical component of the GC system and can become worn out or contaminated over time. Replace the septum regularly to prevent any issues with sample injection and column performance.

5. Keep a log of column usage:

Maintain a record of the column’s usage, including the number of injections and the type of samples analyzed. This information can help you identify any changes in column performance and plan for column replacement if necessary.

By following these tips, you can ensure that your baked GC column remains in optimal condition, providing accurate and reliable results for your analyses.

Wrapping it Up: The Importance of Properly Baking a GC Column

In conclusion, the process of baking a GC column is a crucial step in ensuring accurate and reliable results in gas chromatography. By following the steps outlined in this article, you can effectively prepare, bake, and maintain your GC column for optimal performance.

Properly baking a GC column helps to remove any contaminants or impurities that may be present, ensuring that your column is clean and ready for use. This process also helps to restore the stationary phase, improving the efficiency and resolution of your separations.

It is important to note that the baking process should be done carefully and with precision. Any mistakes or shortcuts taken during this step can lead to poor chromatographic results and wasted time and resources.

By understanding the importance of baking a GC column and following the recommended procedures, you can ensure that your gas chromatography analyses are accurate, reliable, and consistent. So, don’t overlook the significance of this step in your analytical workflow. Take the time to properly bake your GC column and reap the benefits of improved chromatographic performance.Learn how to bake a GC column for gas chromatography analysis. Follow these steps to ensure accurate and reliable results.

About The Author

Zeph Grant is a music fanatic. He loves all types of genres and can often be found discussing the latest album releases with friends. Zeph is also a hardcore content creator, always working on new projects in his spare time. He's an amateur food nerd, and loves knowing all sorts of random facts about food. When it comes to coffee, he's something of an expert - he knows all the best places to get a good cup of joe in town.