Lean Burn is a spark-advance control system. Originally developed as a way to eliminate “troublesome gadgetry,” it is now a multi-spark system. To remove lean burn, you must first determine what the cause of the problem is. You can find out in this article about the system’s origins and removal. If you’re still having trouble with this device, read on to learn how to repair it.

Lean Burn was a spark-advance control system

The original version of the Chrysler Lean Burn engine control system was introduced in 1976. It was a computerized system that controlled spark advance and emissions. While it didn’t control fuel until 1981, it allowed for precise calibration of the mixture. But it wasn’t without issues. One of the biggest was fuel quality. Fuel refineries were forced to pull back on their promise of octane level to automakers, but it was too late to change calculations. The solution came from Chrysler, which installed an anti-ping valve in the hose connecting to the computer. This valve took care of the ping problem.

The system had several benefits, including better economy, fuel economy, and faster starting. However, it had several problems and mechanics were often unwilling to diagnose the problem. Its complexities prevented it from being an adequate replacement for the vacuum and mechanical systems used before. The computer had to be attached to the air cleaner, and the computer was vulnerable to the elements. But this was the first significant step forward for spark advance since the 1920s.

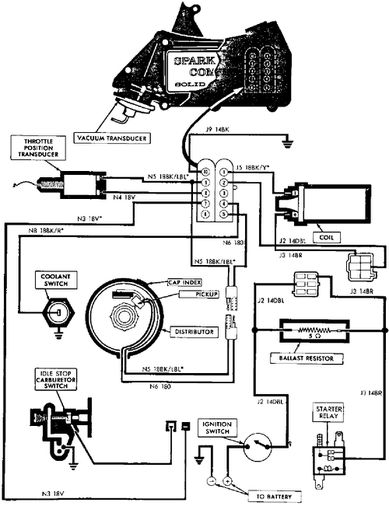

This technology used a sensor that detects engine speed and loads. Engine speed determines when the spark plugs fire. A sensor that measures engine load and throttle position signals the computer to advance spark timing accordingly. This system limits the spark advance to prevent pre-ignition and destructive detonation. In addition, a sensor that detects the temperature of engine coolant limits the spark advance during warm-up. Another sensor that controls the amount of advance during warm-up time and with the choke on limits spark advance during stalls.

Today’s lean-burn technology makes use of advanced spark plugs. The pre-chamber design admits intake air and fuel through tiny orifices. The spark plug then ignites the fuel-air mixture and ejects the flame. The system requires fewer parts and maintenance. It is also more responsive to load changes. Its open-chamber design also allows it to react quickly to load changes.

It was designed to eliminate “troublesome gadgetry”

The Chrysler Electronic Lean Burn fuel system was one of the first computerized control designs in the automobile industry. Although this system caused frequent problems, it was still widely used in all sizes of engines. It was designed to eliminate “troublesome gadgetry” by eliminating the need for air pumps, EGR valves, and other add-on emission control devices. The Chrysler system had no cylinder deactivation valves, so there was no need for an air pump, vacuum advances, or special heat shields. This was because of a unique combustion chamber design and precise spark timing.

It is a multi-spark system

Multi-spark ignition works much like a Zippo when it comes to starting a fire. The ignition coil is charged for the next spark after two engine revolutions, and in this way, the coil has the ability to generate up to five sparks in one millisecond. This requires a high-energy ignition system and specialized components. Consequently, the process of ignition is significantly faster. In some cases, it can reduce fuel consumption by as much as four percent.

The Brisk Multi-Spark Plug has three gaps arranged in series. This design produces three sparks within the firing tip, which eliminates the need for traditional style ground electrodes. The result is improved combustion efficiency and a reduction of unburned fuel/air emissions. Brisk Multi-spark plugs are a proven option in high-performance and racing applications. The Multi-spark plugs are available in multiple heat ranges to match all applications.

A multi-spark ignition system includes two spark plugs inside the cylinder, each having a different heat range and addressing both pre-ignition and ignition. During the first condition, only one spark plug operates while the second condition requires both spark plugs to operate. The second condition requires a different spark plug. It is a multi-spark system that works by receiving time information from the ignition coil. The second spark plug is discharged by the ignition coil, but the current flow in the ignition coil determines the timing of this process.

High-speed combustion causes higher levels of misfire and partial combustion. Multiple spark systems help to reduce this risk by advancing the phasing of the main combustion and initiating flame kernal development with the first spark discharge. The system also reduces the emission of pollutants. In addition, it is more efficient. It has several benefits over traditional combustion systems. The multi-spark ignition system can be used in lean operation, and it doesn’t require the use of CDI.

It causes lean burn

If your car’s computer is causing you to run lean, you may want to replace it. While some people may be inclined to believe that this kind of computer is junk, it is actually very effective and can last for as long as 20 years. Before the advent of the Lean Burn system, computers were attached to the engine’s hot shaking motor. Recently, Lean Burn computers were moved to the fender behind the battery to reduce vibration and heat.

The most common examples of lean-burn engines are automobiles and heavy-duty engines. These engines utilize the concept to make vehicles with low emissions. They do so by using an efficient air-gas management system. This approach to engine design can reduce the cost of costly aftertreatment, which is used to reduce the amount of NOx produced as the cylinders are heated. These systems also reduce the cost of continuous electrical power and can reduce the amount of exhaust gases a car emits.

In the past, Honda engines that used lean-burn had a parallel intake and fuel system. The pre-chamber used an ideal fuel/air ratio to begin combustion. The main chamber used a larger, leaner mix, which was ignited through the primary combustion chamber. Lean-burn engines used carbureted fuels, compound vortex controlled combustion, or MPI. These cars still had a similar system, but with different parts.

The most common example of a lean-burn car is a Honda CRX. These engines use a stratified charge approach, which means that the air-fuel ratio is not the same throughout each cylinder. It is possible to concentrate more fuel in a spark plug tip, which requires richer fuel for proper ignition and flame spread. The remaining cylinders use progressively leaner fuel. Nevertheless, the air-fuel ratio of these cars can be as high as 22:1.

It can be converted to electronic ignition

Most vehicles built before 1994 are compatible with electronic ignition systems, so converting your vehicle to an electronic ignition system is quite simple. Aftermarket coils have no ballast resistors, so you can eliminate the need for a relay. You also don’t need to replace the ignition coil, as the new coil is designed for use with the new electronic ignition system. To begin, you’ll need to unplug the old ignition coil, and disconnect the negative lead from the ignition coil. Install a new ignition coil with a new electronic ignition module.

Many older cars were built with less-than-optimal ignition systems. Lean Burn systems were commonly installed in cars made by Chrysler in the mid to late-70s. The Lean Burn system was supposedly the next big leap in electronic ignition control, but its preprogrammed data was prone to malfunction. Also, it was attached to the side of the air cleaner, subject to excessive heat and vibration.

The ignition system used in the Lean Burn system looks very similar to the Slant Six distributors. It uses the same 6 point reluctor as other electronic ignition systems, but it is controlled electronically instead of mechanically. It can be controlled by a computer that monitors engine temperature, vacuum signals, and the O2 sensor. Consequently, the Lean Burn system produces lower emission levels than a traditional ignition system.

This conversion can also be used for vehicles built before 1992. A conversion kit is available for vehicles built before this date. The electronic ignition system will include a vacuum advance and pickup coil, as well as the armature. The pickup coil will generate a small magnetic field. The ignition coil receives this signal and sends it to the ignition module. The distributor then sends a current to the spark plugs, causing combustion.

About The Author

Mindy Vu is a part time shoe model and professional mum. She loves to cook and has been proclaimed the best cook in the world by her friends and family. She adores her pet dog Twinkie, and is happily married to her books.