Last Updated on September 17, 2022

If you need to replace the track on your excavator, you’ve probably found that the link is not lining up correctly. There are a few things you can do to ensure the track is lined up properly, including finding the master pin and adjusting the track sag. This article will walk you through all of those steps. Hopefully, you’ll have your machine back on track in no time.

Links eject from excavator track

If you’re wondering “How to eject links from excavate track?” you’ve come to the right place. There are several reasons for this condition. In some cases, it can be caused by improper track adjustment or poor track use. In other cases, the link may just become detached from its rubber connection. Either way, preventing this problem is easy. Learn what causes it and how to prevent it.

If your excavator’s track becomes derailed, try to avoid riding on embedded links. This can result in catastrophic failure. To avoid this problem, avoid quick turns in bumpy fields or driving over sharp objects in fields. Instead, plan your jobs around short travel distances and use transport for longer distances. But if you’re unsure, watch your movements carefully. Once you’ve figured out how to eject links from excavator track, you’re ready to replace the damaged links.

If you want to install new links, you can use a sledgehammer to break the shank of the bolt. Be sure to use a sledgehammer to break the shank of the bolt. Once the bolt is loose, clean the bottom of the shoes thoroughly with a wire brush. Make sure to clean the area where the new chain will make contact with the old one. Finally, install new chains.

To remove links from excavator track, follow these steps. First, use the master link, which is made up of two interlocking pieces. The other piece is attached to the track shoe. If the master link is twisted, use a bolt remover to loosen it. After removing the master link, lift the lower track from the machine. You can also use a torch to cut the link.

Master pins removed from excavator track

To remove the master pin from your excavator track, you must first remove the snap ring. The snap ring will be attached to the end of the track, and if the ring is removed, the track will split. Pull out the master pin from the outer side of the track and insert it into the other end. You should be careful not to lose the rings! After removing the master pin, you can replace the snap ring with a new one.

The process to replace the track master pins is simple. The excavator will turn on its side. If the pins are loose, the excavator will not turn properly. In some cases, they may separate from the track, and this could result in severe injuries or even death. To prevent this from happening, you can use track master pin oil. It provides corrosion protection and is strong enough to withstand the excavator’s movements.

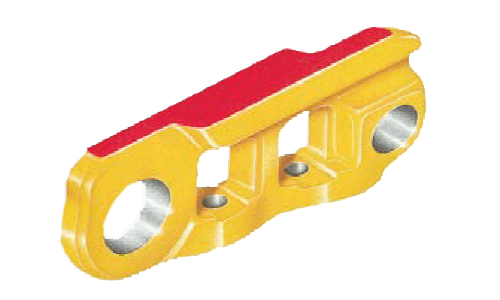

The master pins are a key component to your excavator’s track. These pieces of track hold the movable links together. Oftentimes, they have a corresponding hole for the master pin. The master pins are necessary to prevent side-to-side movement of the track chain. They can also help to prevent a track from breaking or falling. This can cause serious damage to your excavator, so make sure to have them checked before using the excavator.

Using a track-master pin press machine is an efficient way to remove a master pin from an excavator. They are commonly used in workshops. Their all-metal construction makes them easier to install. Additionally, they come with a unique inner cavity for added support. Whether you need to remove one or remove the entire track, the X-Cut rod is the best choice.

Finding master pin

To remove an excavator link, it is important to locate the master pin. There are two parts to the master pin, one attached to the end of the track and the other attached to the opposite end. Pulling out the master pin will split the track. Look for a dot on the outer side of the track with a snap ring on the inner side. To pull it out, push the pin out from the inner side and back into the link.

The master pin is smaller than other pins on the master link bushing, which will seal out dirt and water from entering the joint. If your track does not have a master pin, you may need to disassemble the entire excavator track to find it. The master pin on some excavators is a cotter pin. Some track service shops have tools to repair the master pin. If you don’t have the right tools, you may have to dismantle the entire track to get to it.

When disassembling the track, remember to grease the track links before removing them. Grease will make the tracks last 20-40% longer. When disassembling the track, take care not to damage the track parts, as the seals can be difficult to remove. Using fresh grease on track pins and bushings will help prevent the link from getting stuck. A grease-lubricated track link assembly is a direct replacement for a sealed link assembly.

There are two parts to the master link pin. The distal part has threads that match the slots in the pin bores 118. These threads mate with the first and second threaded pin bores. A master link pin may also have other suitable means to mate with the other pin. These two parts may have different sizes. Once you have located the master pin, you can remove the link from the excavator.

Adjusting track sag

Aside from checking for sag, it is also crucial to check for track tension. The tracks of the excavator are attached to the hydraulic arm or boom. To adjust the tension, lift the tracks off the ground and remove any debris. Then, unscrew the cover plate on the track adjuster valve or grease fitting. Check the track sag and adjust the link according to specifications in the operator’s manual.

The manufacturer of the rubber tracks will specify the recommended track sag distance for the machine. This measurement will depend on the weight and construction of the undercarriage. If the rubber track is not working properly, it is most likely due to worn out undercarriage parts. In such a case, you can check the measurements in the operating manual or the manual. VemaTrack dealers will offer advice for replacement steel undercarriage parts.

A loose track can cause the excavator to rock and pop when turning. This reduces the power of the track and causes additional wear and tear. To prevent this, it is crucial to inspect the tracks on a regular basis. The tracks must be properly adjusted if they are loose and can contact the frame. If the track is too loose, you may need to adjust it once again.

Aftermarket track adjusters are an excellent alternative to genuine OEM ones. Genuine springs are only a fraction of the cost of an assembly. You can also opt for a track adjuster made of high-quality steel. Aftermarket track adjusters come with a manufacture’s defect warranty and are available without downtime. When you are ready to replace your track adjuster, remember to unlink the excavator’s track.

Finding master pin on excavator track

In order to find the master pin on your excavator track, you must first disassemble the track. New tracks require disassembly, but older models do not. CAT uses a cotter pin to hold the master pin. It is often smaller than the other pins, but the CAT uses a larger bore hole to fit the master link bushing. In addition, the master pin may have special washers around it to prevent dirt and water from entering the pin area.

To find the master pin on the track, you must first unbolt the tracks. This may require a portable press to remove the bolts on the master pin pad. If this method is not enough, you can use a blowtorch to cut the link. You will then have to weld a replacement master pin. This process should not be too complicated. The excavator track may have several master pins.

The master pin is usually located in the middle of the tracks. It’s the only pin on the track, so pulling it out will split the track. The master pin will usually be a dot on the outer track, with a snap ring on the inner side. To pull it out, you need to unsnap the snap ring, which will release pressure on the master pin. Alternatively, you can use a sledgehammer to strike the pin with enough force to knock it out.

Knowing how to change the track on an excavator can be vital when you’re out on the job. Changing the track can help you perform necessary repairs in the field, or in remote locations. Some dealerships and mining companies use hydraulic pin presses to change track assemblies, but this method is not necessary for everyone. It requires special tools and follows specific procedures. And if you don’t have a hydraulic pin press, don’t worry. There are other ways to change the track on a heavy equipment.

About The Author

Mindy Vu is a part time shoe model and professional mum. She loves to cook and has been proclaimed the best cook in the world by her friends and family. She adores her pet dog Twinkie, and is happily married to her books.