Last Updated on July 27, 2023

Welcome to our article on the cost of detailing a plane. If you’re a plane owner or enthusiast, you know that keeping your aircraft in top condition is essential for both maintenance and resale value. But how much does it actually cost to detail a plane? In this article, we will explore the various factors that can affect the cost of plane detailing, including exterior and interior services, as well as additional services that may be available. We will also compare costs between different detailing providers and provide tips for finding affordable plane detailing services. So, let’s dive in and discover the importance of regular plane detailing and considerations when budgeting for this essential service.

Factors that affect the cost of plane detailing

When it comes to detailing a plane, there are several factors that can affect the cost of the service. These factors include:

- The size and type of the plane: Larger planes generally require more time and resources to detail, which can increase the cost.

- The condition of the plane: If the plane is in poor condition and requires extensive cleaning and restoration, the cost may be higher.

- The level of detailing desired: Different levels of detailing services are available, ranging from basic cleaning to more comprehensive restoration. The more detailed the service, the higher the cost.

- The location of the detailing provider: The cost of plane detailing can vary depending on the location of the service provider. Higher costs may be associated with providers in more expensive areas.

- The reputation and experience of the detailing provider: Providers with a strong reputation and extensive experience may charge higher prices for their services.

Considering these factors can help you understand why the cost of plane detailing can vary and allow you to make an informed decision when choosing a service provider.

Exterior detailing services and their costs

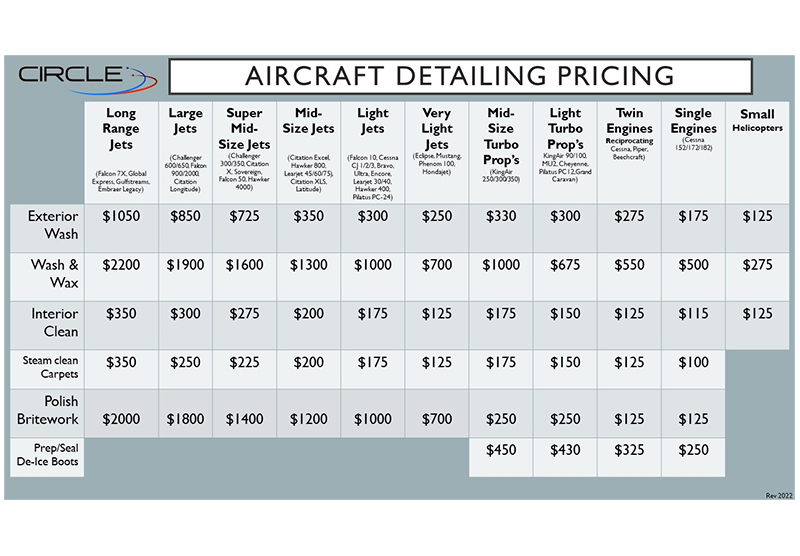

Exterior detailing services play a crucial role in maintaining the appearance and condition of a plane. These services typically include washing, waxing, and polishing the exterior surfaces of the aircraft. The cost of exterior detailing can vary depending on several factors, such as the size of the plane, the level of dirt and grime, and the type of products and equipment used.

One of the main factors that affect the cost of exterior detailing is the size of the plane. Larger planes require more time and effort to clean and polish, which can result in higher costs. Additionally, the level of dirt and grime on the exterior surfaces can also impact the cost. If the plane has been exposed to harsh weather conditions or has not been cleaned for a long time, it may require more extensive cleaning and detailing, leading to increased costs.

The type of products and equipment used for exterior detailing can also influence the cost. High-quality cleaning and polishing products, as well as advanced equipment, can result in a higher price tag. However, these products and equipment often provide better results and ensure a longer-lasting finish, making them worth the investment.

Overall, the cost of exterior detailing services can range from a few hundred to several thousand dollars, depending on the specific requirements of the plane. It is essential to consider these factors when budgeting for plane detailing to ensure that you receive the best possible service within your budget.

Interior Detailing Services and Their Costs

When it comes to plane detailing, the interior is just as important as the exterior. After all, passengers spend most of their time inside the aircraft, so it’s crucial to keep the interior clean and well-maintained. Interior detailing services typically include cleaning and sanitizing the seats, carpets, and upholstery, as well as polishing and conditioning the leather surfaces. The cost of these services can vary depending on the size of the plane and the level of detail required.

For smaller planes, such as private jets or turboprops, interior detailing can range from $500 to $1,000. This includes a thorough cleaning of the cabin, including the cockpit, galley, and lavatory. For larger commercial planes, the cost can be significantly higher, ranging from $2,000 to $5,000 or more. These planes have more extensive interiors and require more time and effort to detail.

In addition to basic cleaning, some detailing providers offer additional services such as stain removal, odor elimination, and leather restoration. These services can add to the overall cost, but they are often worth it for maintaining the pristine condition of the interior.

5. Additional services and their costs

When it comes to plane detailing, there are several additional services that you may want to consider. These services can enhance the overall appearance and functionality of your aircraft, but they may also come at an additional cost. Some of the additional services offered by plane detailing providers include:

- Paint correction: This service involves removing scratches, swirl marks, and other imperfections from the aircraft’s paintwork. The cost of paint correction can vary depending on the extent of the damage and the size of the aircraft.

- Headlight restoration: Over time, the headlights of an aircraft can become dull and hazy, reducing visibility. Headlight restoration involves cleaning and polishing the headlights to improve their clarity. The cost of this service is typically affordable.

- Engine cleaning: Keeping the engine of your aircraft clean is essential for its performance and longevity. Engine cleaning services can remove dirt, grease, and other contaminants from the engine, ensuring optimal functioning. The cost of engine cleaning can vary depending on the size and complexity of the engine.

- Odor removal: If your aircraft has unpleasant odors, such as from smoke or pets, odor removal services can help eliminate them. The cost of odor removal can depend on the severity of the odor and the size of the aircraft.

- Window tinting: Tinting the windows of your aircraft can provide privacy, reduce glare, and protect against harmful UV rays. The cost of window tinting can vary depending on the number and size of the windows.

It’s important to consider your specific needs and budget when deciding which additional services to include in your plane detailing package.

Comparison of costs between different detailing providers

When it comes to plane detailing, the cost can vary significantly depending on the provider. It is important to compare the costs and services offered by different detailing providers to ensure you are getting the best value for your money. Here are some factors to consider when comparing costs:

- Experience and reputation of the detailing provider

- Size and type of the plane

- Extent of detailing required

- Location of the detailing provider

- Additional services included in the package

It is recommended to obtain quotes from multiple detailing providers and compare them based on the above factors. Keep in mind that the cheapest option may not always be the best choice, as quality of service should also be taken into consideration.

Additionally, it is important to read reviews and testimonials from previous customers to get an idea of the level of satisfaction and quality of work provided by each detailing provider. This will help you make an informed decision and choose a provider that meets your needs and budget.

Tips for finding affordable plane detailing services

When it comes to finding affordable plane detailing services, there are a few tips that can help you save money without compromising on quality.

1. Shop around

Don’t settle for the first detailing provider you come across. Take the time to research and compare prices from different companies. This will give you a better idea of the average cost and help you find the best deal.

2. Look for discounts or promotions

Many detailing providers offer discounts or promotions, especially during off-peak seasons. Keep an eye out for these deals and take advantage of them to save some money.

3. Consider package deals

Some detailing providers offer package deals that include both exterior and interior detailing services. These packages are often more cost-effective than getting each service separately.

4. Ask for recommendations

Reach out to other plane owners or aviation enthusiasts for recommendations on affordable detailing services. They may have insider knowledge or know of providers who offer competitive prices.

By following these tips, you can find affordable plane detailing services that fit within your budget without compromising on the quality of the service.

Importance of regular plane detailing for maintenance and resale value

Regular plane detailing is essential for maintaining the overall condition and resale value of the aircraft. Just like any other vehicle, planes are exposed to various environmental factors that can cause damage and wear over time. By regularly detailing the plane, owners can protect the exterior and interior surfaces from harmful elements such as UV rays, dirt, and pollutants.

Exterior detailing, which includes washing, waxing, and polishing, not only enhances the plane’s appearance but also helps to prevent corrosion and paint damage. Interior detailing, on the other hand, involves cleaning and conditioning the upholstery, carpets, and other surfaces, ensuring a comfortable and hygienic environment for passengers.

Regular detailing also plays a crucial role in maintaining the resale value of the aircraft. Potential buyers are more likely to be attracted to a well-maintained plane that looks and feels clean and fresh. A detailed maintenance history, including regular detailing, can also provide reassurance to buyers about the overall condition and care of the aircraft.

Therefore, investing in regular plane detailing is not only beneficial for the present enjoyment and comfort of the owner and passengers but also for the long-term value and marketability of the aircraft.

Considerations when budgeting for plane detailing

When it comes to budgeting for plane detailing, there are several important considerations to keep in mind. Firstly, it is essential to understand that the cost of plane detailing can vary significantly depending on various factors. These factors include the size and type of the aircraft, the level of detailing required, and the location of the service provider.

One important consideration is the size and type of the aircraft. Larger planes generally require more time and resources to detail, which can result in higher costs. Additionally, different types of aircraft may have specific detailing requirements, which can also impact the overall cost.

Another consideration is the level of detailing required. Some planes may only require basic cleaning and maintenance, while others may need more extensive services such as paint correction or upholstery restoration. The level of detailing required will directly affect the cost.

Lastly, the location of the service provider can also impact the cost of plane detailing. Different regions may have varying labor and material costs, which can influence the overall price.

Considering these factors and obtaining quotes from different detailing providers can help in budgeting for plane detailing effectively.

Wrapping it Up: The Importance of Regular Plane Detailing

After exploring the various factors, services, and costs associated with plane detailing, it is clear that regular maintenance is crucial for both the longevity and resale value of your aircraft. Regular plane detailing not only enhances the appearance of your plane, but it also protects it from the damaging effects of dirt, grime, and UV rays.

By investing in exterior detailing services, such as washing, waxing, and polishing, you can ensure that your plane maintains its sleek and pristine look. Interior detailing services, on the other hand, focus on cleaning and restoring the cabin, upholstery, and other interior components, creating a comfortable and inviting environment for passengers.

Additionally, considering the costs of additional services, such as paint touch-ups, leather conditioning, and engine cleaning, can help you make informed decisions when budgeting for plane detailing.

Ultimately, regular plane detailing is not just a luxury, but a necessity for any aircraft owner who wants to protect their investment and maintain its value over time. So, don’t overlook the importance of this essential maintenance task and start searching for affordable plane detailing services today!

Discover the factors that affect the cost of plane detailing and find affordable services for maintaining your aircraft’s value.

About The Author

Orochi Konya is a student of the web. He has been dabbling in it since he was young, and has become an expert in his own right. He loves all things digital, from making websites to programming to social media. In his spare time, Orochi enjoys indulging in his other passion: music. He loves listening to all kinds of music and often spends hours creating playlists on Spotify. He also enjoys drawing manga and watching anime in his free time. Orochi is a friendly pop-culture guru who is always happy to chat about the latest trends in both Japan and the U.S.