Last Updated on July 27, 2023

Welcome to our comprehensive guide on how to make hollow fire eating torches. Fire eating is a mesmerizing and daring performance art that has captivated audiences for centuries. In this article, we will delve into the basics of fire eating, the materials you will need, and the step-by-step process of preparing your very own hollow fire eating torches. Safety is of utmost importance when it comes to fire eating, so we will also discuss the necessary safety measures to ensure a risk-free experience. Additionally, we will provide tips for mastering the proper technique and troubleshooting common issues that may arise. Whether you are a beginner or an advanced fire eater, this guide has something for everyone. So, let’s dive in and unlock the secrets of this thrilling art form!

Understanding the Basics of Fire Eating

Before you start making your own hollow fire eating torches, it’s important to have a good understanding of the basics of fire eating. Here are some key points to keep in mind:

- Fire eating is a dangerous art form that requires skill and practice.

- It involves extinguishing a flame by placing it in your mouth.

- Fire eaters must have a strong understanding of fire safety.

- It is important to start with small flames and gradually work your way up to larger ones.

By understanding these basics, you will be better prepared to make and use your own hollow fire eating torches.

Gathering the Necessary Materials

Before you can start making your own hollow fire eating torches, you need to gather all the necessary materials. This includes:

- 1. Metal tubing: Look for metal tubing that is heat-resistant and can withstand high temperatures. Copper or stainless steel tubing are good options.

- 2. Wooden dowels: You will need wooden dowels that are the same length as the metal tubing. These will serve as the handles for your torches.

- 3. Kevlar wick: Kevlar wick is essential for creating the flame on your torches. Make sure to get enough wick to wrap around the metal tubing.

- 4. Heat-resistant tape: Use heat-resistant tape to secure the kevlar wick to the metal tubing. This will ensure that the wick stays in place while you are performing.

- 5. Fire extinguisher: Safety should always be your top priority when fire eating. Make sure to have a fire extinguisher nearby in case of emergencies.

Once you have gathered all these materials, you will be ready to move on to the next step of preparing your hollow fire eating torches.

Preparing the Hollow Fire Eating Torches

Once you have gathered all the necessary materials, it’s time to start preparing the hollow fire eating torches. This step is crucial as it ensures that the torches are safe to use and will provide the desired effect.

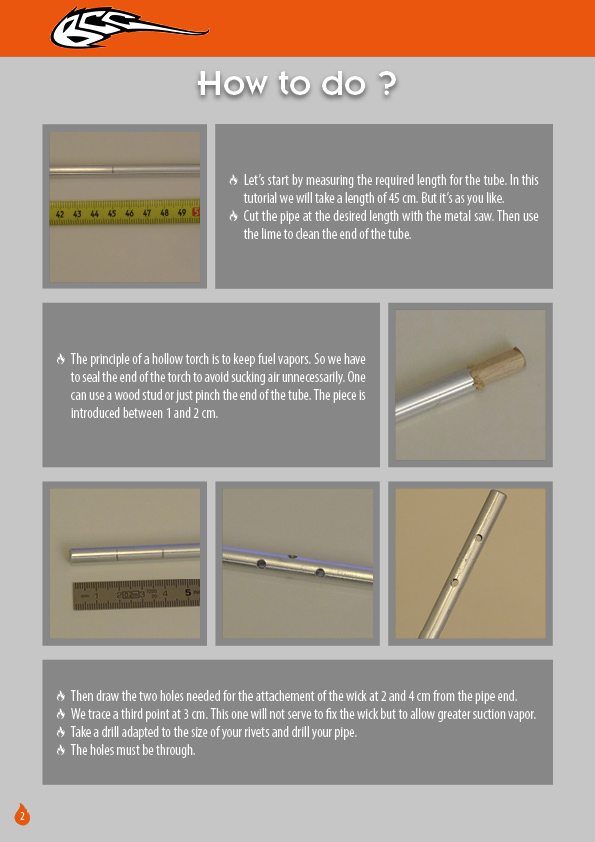

First, you will need to cut the metal tubing into the desired length for your torches. It is recommended to use stainless steel tubing as it is durable and resistant to heat. Measure the length carefully and use a hacksaw or pipe cutter to make clean cuts.

Next, you will need to attach the wick to the metal tubing. Take a piece of Kevlar wick and wrap it tightly around one end of the tubing. Use a heat-resistant thread to secure the wick in place. Make sure the wick is tightly wrapped and there are no loose ends.

After attaching the wick, you will need to soak it in a fire-resistant fuel. Common fuels used for fire eating include lamp oil or white gas. Fill a container with the fuel and carefully dip the wick into it. Allow the wick to soak for a few minutes, ensuring that it is fully saturated.

Once the wick is soaked, remove it from the fuel and let it dry for a few minutes. This will allow any excess fuel to evaporate, reducing the risk of accidents during performance. It is important to handle the soaked wick with care and avoid any open flames or sparks.

Repeat the process for each torch, ensuring that all the wicks are properly attached and soaked. Once the torches are prepared, it is important to store them in a safe and dry place until they are ready to be used.

4. Preparing the Hollow Fire Eating Torches

Once you have gathered all the necessary materials, it’s time to prepare your hollow fire eating torches. Follow these steps to ensure they are ready for use:

- Measure and cut the wick: Take your wick material and measure it according to the length you desire for your torch. Use a sharp pair of scissors or a utility knife to cut the wick to the desired length.

- Attach the wick to the tube: Take one end of the wick and insert it into the hollow tube. Make sure it is securely attached and won’t come loose during use. You can use a small amount of adhesive or tape to hold it in place if needed.

- Secure the tube: Once the wick is attached, make sure the tube is securely fastened to the handle. You can use screws, bolts, or any other method that will keep the tube in place and prevent it from coming loose while you are performing.

- Soak the wick: Before using your hollow fire eating torches, it’s important to soak the wick in a fire-resistant fuel. This will ensure that the wick burns properly and doesn’t pose a safety risk. Use a fuel specifically designed for fire eating, such as lamp oil or white gas.

By following these steps, you will have properly prepared your hollow fire eating torches for use. It’s important to always prioritize safety and take the necessary precautions when working with fire.

6. Learning the Proper Technique

Once you have your hollow fire eating torches prepared and you have taken all the necessary safety precautions, it’s time to learn the proper technique for fire eating. Here are some key points to keep in mind:

- Start with a small flame: When you first begin practicing fire eating, it’s important to start with a small flame. This will help you get used to the sensation of the fire and allow you to build up your tolerance gradually.

- Hold the torch correctly: Grip the torch firmly but not too tightly. Hold it at the base, making sure to keep your fingers away from the flame.

- Angle the torch: Tilt the torch slightly upwards so that the flame is pointing towards the roof of your mouth. This will help prevent any accidental burns.

- Control your breath: Take slow, controlled breaths while performing fire eating. This will help you maintain control and prevent any mishaps.

- Extinguish the flame: After each fire eating trick, make sure to extinguish the flame completely before attempting another one. This will help prevent any accidental fires.

Remember, learning the proper technique for fire eating takes time and practice. It’s important to start slow and gradually build up your skills. Always prioritize safety and never attempt any advanced tricks without proper training and supervision.

Practicing Fire Eating with Hollow Torches

Once you have prepared your hollow fire eating torches and learned the proper technique, it is time to start practicing. However, it is important to remember that fire eating is an extremely dangerous activity and should only be attempted by trained professionals.

Before you begin, make sure you are in a safe and controlled environment. Clear any flammable objects from the area and have a fire extinguisher nearby. It is also a good idea to have a safety spotter present in case of emergencies.

Start by practicing basic moves such as the flame transfer and the vapor pull. These moves will help you build confidence and control over the flames. As you become more comfortable, you can start incorporating more advanced tricks and techniques.

Remember to always prioritize safety and never attempt any moves that you are not fully confident in. Fire eating is a skill that takes time and practice to master, so be patient with yourself and take it slow.

With dedication and practice, you can become a skilled fire eater and wow audiences with your mesmerizing performances.

Troubleshooting Common Issues

Fire eating can be a thrilling and mesmerizing performance art, but it is not without its challenges. As you begin your journey into fire eating with hollow torches, you may encounter some common issues that can hinder your progress. Here are a few troubleshooting tips to help you overcome these obstacles:

1. Difficulty lighting the torches

If you’re having trouble lighting your hollow torches, make sure you are using the correct fuel and that it is properly soaked into the wick. Additionally, check that the wick is not too tightly packed, as this can prevent proper airflow and hinder ignition.

2. Excessive smoke or soot

If you notice excessive smoke or soot while fire eating, it could be a sign of improper fuel usage or a dirty wick. Ensure that you are using a clean wick and that the fuel is properly soaked into it. Avoid using fuels with high levels of impurities, as they can contribute to excessive smoke and soot.

3. Difficulty extinguishing the flames

Extinguishing the flames can be challenging, especially if you are new to fire eating. To safely extinguish the flames, gently blow on the torches or use a fire blanket to smother the fire. Avoid using your hands or any flammable materials to put out the flames.

By troubleshooting these common issues and practicing proper fire safety techniques, you can enhance your fire eating skills and create a captivating performance. Remember to always prioritize safety and seek guidance from experienced fire eaters if you encounter any difficulties.

Tips for Advanced Fire Eaters

For those who have mastered the art of fire eating and are looking to take their skills to the next level, here are some tips to help you become an advanced fire eater.

1. Experiment with Different Fuels

While most fire eaters use standard lamp oil or paraffin, advanced fire eaters often experiment with different fuels to create unique and visually stunning effects. Some popular options include rubbing alcohol, white gas, and even vodka. However, it is important to note that these fuels can be more dangerous and should only be used by experienced fire eaters.

2. Incorporate Props and Tricks

Advanced fire eaters often incorporate props and tricks into their performances to add an extra element of excitement. This can include fire breathing, fire juggling, or even fire poi spinning. These additional skills not only impress audiences but also showcase the performer’s versatility and expertise.

Remember, as an advanced fire eater, safety should always be your top priority. Always perform in a controlled environment, have a safety spotter present, and never attempt dangerous stunts without proper training and experience.

Conclusion: Mastering the Art of Fire Eating

As we come to the end of this comprehensive guide on how to make and use hollow fire eating torches, it is important to reflect on the journey we have taken. Throughout this article, we have explored the basics of fire eating, gathered the necessary materials, prepared the torches, and learned the proper technique. We have also discussed safety measures, troubleshooting common issues, and provided tips for advanced fire eaters.

Fire eating is an ancient and mesmerizing art form that requires dedication, practice, and a deep understanding of safety precautions. By following the steps outlined in this guide, you can embark on a thrilling journey of mastering this unique skill.

Remember, fire eating is not for the faint of heart. It requires discipline, focus, and a respect for the power of fire. Always prioritize safety and never attempt any fire eating tricks without proper training and supervision.

So, whether you are a beginner or an experienced fire eater, take these lessons to heart and continue to push the boundaries of your abilities. With practice and perseverance, you can become a true master of the art of fire eating.Learn how to make hollow fire eating torches and safely practice fire eating techniques with this comprehensive guide.

About The Author

Alison Sowle is the typical tv guru. With a social media evangelist background, she knows how to get her message out there. However, she's also an introvert at heart and loves nothing more than writing for hours on end. She's a passionate creator who takes great joy in learning about new cultures - especially when it comes to beer!