Last Updated on September 17, 2022

Whether you’re unsure about how to install a diaphragm pump or you’ve never installed one before, this article will provide you with some useful tips and tricks for installing these pumps. We’ll cover how to choose the right type of pump for your needs, including whether you want a self-priming or air operated model, as well as the proper air pressure and airline size for your installation.

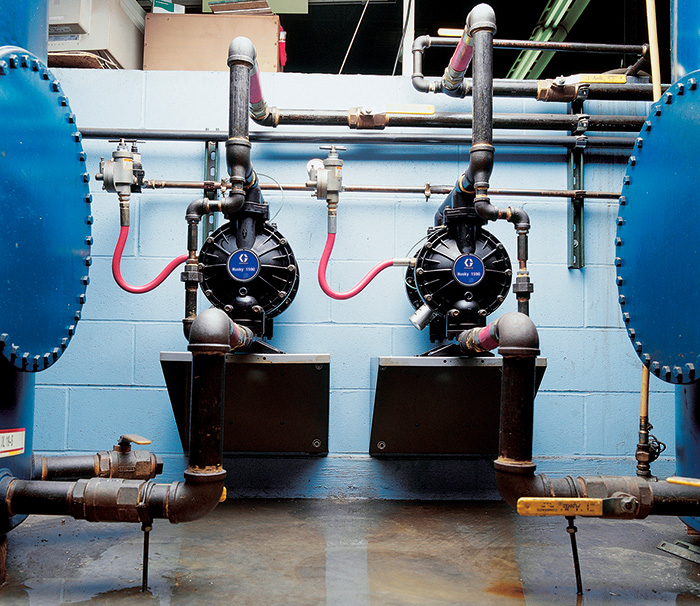

Air operated double diaphragm pump (AODD)

An AODD pump is used in a variety of applications. Its efficiency is highly dependent on the amount of compressed air available. This supply must be at a similar or higher pressure than the fluid being pumped. This limits its use to low-pressure applications. The differential pressure between the pumped fluid and the air supply determines the pump’s speed. As the air pressure increases, the pump speed also increases. Because of this, it may be necessary to regulate the pressure and flow to ensure an efficient pumping process.

AODD pumps are designed for tough jobs. They feature a flexible diaphragm connected to a shaft, which moves back and forth to produce pumping action. The fluids being pumped through an AODD pump are then expelled through the piping system. Pumping Solutions carries an array of AODD pumps from leading diaphragm pump manufacturers. One of these companies is Wilden, which invented the air operated double diaphragm pump in 1955.

Because the air side of the AODD pump comes in contact with the fluid, it is important to choose materials that are compatible with the fluid. As the diaphragm may not be completely leak-proof, chemical compatibility is crucial to ensure the longevity of the pump. Polypropylene, stainless steel, and coated metal components make AODD pumps compatible with a variety of chemicals.

One advantage of an AODD pump over centrifugal pumps is its ability to handle very thick liquids. Despite the fact that they require relatively little maintenance and assembly, AODD pumps are the best choice for high-pressure, shear-sensitive materials. Unlike mechanically operated diaphragm pumps, AODD pumps can also be used in hazardous environments. The AODD pump is an excellent choice for on-demand and intermittent requirements.

Self-priming

A self-priming diaphragm pump has a low suction lift, which reduces the pressure required to operate. Its diaphragm is made from PTFE or rubber, and works in conjunction with a ball or flapper valve to control flow direction and the amount of fluid at discharge. The Tapflo Diaphragm Pump is one of the most common pumps on the market today. Its features include high volume and low pressure, which makes it suitable for a range of different applications.

The self-priming diaphragm pump works in a wide range of environments, such as air and water mixtures. The pump uses an air-water mixture to transform this air into fluid. Moreover, it is widely used in wastewater treatment. The underlying technology is very similar to centrifugal pumps. It also offers a wide range of options and functions. However, some people still find them difficult to use.

The impeller efficiency of centrifugal pumps plays a crucial role in the self-priming function of these pumps. In addition, a solid-filled liquid can accumulate in the recirculation port, impeding the flow of fluid and generation of the liquid ring. Further, debris on the impeller reduces the ability of the pump to generate a low-pressure region. Aside from this, internal clearances increase with wear. Improper assembly of the pump may affect these clearances.

The self-priming diaphragm pump is capable of enduring periods of dry running. This feature is useful if the suction line is not filled. It can suck up air in the suction pipe during start-up and then expel it through the delivery line. After eliminating the air, the pump will operate normally. The pump is also able to handle a variety of pressure levels.

Inlet airline size

Air operated diaphragm pumps are widely used in a variety of industrial settings. In addition to water and chemical applications, diaphragm pumps are used in petrochemical, metal fabrication, mining, construction, and food and beverage facilities. Some models come with an air line valve to control the flow of liquid. Some models also come with fluid discharge valves for discharge of fluid. When choosing the correct air operated diaphragm pump for your application, you should consider the following factors:

Inlet airline size: This measurement refers to the size of the pump’s air lines. The larger the inlet airline size, the lower the air pressure. If the air line size is too small, the diaphragm may fail. If this occurs, the fluid may be contaminated with dissolved solids, which can lead to rapid pump failure. Air filter/regulators are a great addition to any diaphragm pump as they control the air volume and pressure entering the pump.

The size of the air line should match the size of the air valve port. When purchasing AODD pumps, make sure the air line is the correct size for the application. A smaller one will starve the pump of fuel and damage its internal mechanisms. If the air line is too small, upgrade it to a larger size. Upgrading the air line size is a simple process and only takes a few minutes.

Diaphragm pumps are a good choice for many applications. They can be used in industries like metallurgical mining, coating, and water treatment. Air-driven diaphragm pumps can handle a variety of fluids. Generally, they can handle fluids with a low air pressure, while mechanically-driven diaphragm pumps have a higher air-flow requirement.

Inlet air pressure

Diaphragm pumps are commonly used in a variety of applications. They are often used in water treatment facilities, petrochemical facilities, and metal fabrication facilities. In addition to their wide range of uses, diaphragm pumps are also used in food and beverage facilities. Fluid discharge valves are also part of the diaphragm pump. In this article, we’ll cover a few of the more common types and how to check yours.

Firstly, the air supply for an AODD pump is critical to its operation. The pump cannot function properly if the air supply is too low or too high. To avoid this problem, you can install an “Anti-Ice Muffler” and an air filter in your compressed air line. These two measures will prevent the pump from starving itself of compressed air. A back-pressure device is also important.

Another key issue to consider is the size of the air supply line. Air supply lines for diaphragm pumps must be sized correctly. If they are too small, you’ll end up starving the pump of its fuel. For instance, a 3/4-inch air port requires an air supply line of at least 1/2-inch. If you don’t have the proper air supply, you’ll have to buy an air compressor and spend more on the pump.

The first step in determining the proper inlet air pressure for a diaphragm pump is to measure the pressure of the ambient air in the chamber. During air inlet, you’ll find that it is at 80 psi. If you need to use the discharge side, you’ll need to increase the pressure of the air. If you need to pump more air than that, you can try a higher-pressure model, but remember to be careful.

Optimising performance

Optimising performance when installing diaphermal pumps is essential to the smooth running of your system. Pump systems can account for 25-60 percent of energy usage in industrial facilities. While this figure may seem exorbitant, other energy factors pale in comparison. If your pump system is not performing to optimal efficiency, you are not only wasting energy, but also money. Here are some tips to help you optimise your performance.

First, you must determine the exact pressure that actuates the check valves. This pressure will determine the instantaneous delivered flow rate. After determining the pressure, you should use this pressure to design new prototypes. Finally, you must compare numerical results with experimental performance curves to confirm the accuracy of your model. This will allow you to determine if you should modify the pump to achieve a better performance.

Another way to optimise performance when installing diaphragm pumps is to select a system that includes a monitoring device. Monitoring devices are connected to a cloud service that stores performance data. This cloud storage service stores performance data encrypted and securely transmits it to a web dashboard. Then, using a mobile smartphone application or a web-based dashboard, you can view this information at any time.

Another way to optimise performance when installing diaphragm pumps is to choose the right type of diaphragm. An ideal type of diaphragm should have a high-quality, durable seal. In case of leakage, it should be able to tolerate high pressures without damaging the pump. If you’re concerned about your pump’s lifespan, you should choose a metering pump that has a high-performance diaphragm that’s suitable for the application in question.

About The Author

Mindy Vu is a part time shoe model and professional mum. She loves to cook and has been proclaimed the best cook in the world by her friends and family. She adores her pet dog Twinkie, and is happily married to her books.