Last Updated on July 26, 2023

Short Answer

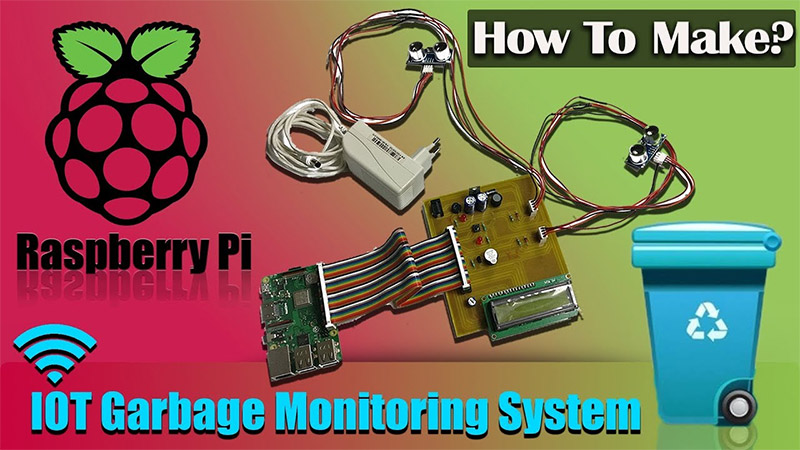

Creating an automatic garbage disposal using Raspberry Pi involves utilizing the capabilities of this small computer to automate the process of disposing waste. By connecting sensors to the Raspberry Pi, it can detect when the garbage bin is full and trigger the disposal mechanism. This innovative solution not only simplifies waste management but also promotes efficiency and convenience. With the right programming and hardware setup, individuals can harness the power of Raspberry Pi to create a smart garbage disposal system that enhances cleanliness and reduces manual effort.In today’s world, waste management is a pressing issue that requires innovative solutions. One such solution is the creation of an automatic garbage disposal system using Raspberry Pi. This article will guide you through the process of building your own system, from understanding the basics of Raspberry Pi to programming and testing the disposal process. We will also explore the benefits of this technology and how it can enhance waste management in the future. By embracing innovation and utilizing the capabilities of Raspberry Pi, we can create a more efficient and sustainable waste management solution. So let’s dive in and discover the world of automatic garbage disposal with Raspberry Pi.

Understanding the basics of Raspberry Pi and its capabilities

- Raspberry Pi is a small, affordable computer that can be used for various projects

- It is capable of running a full operating system and can be programmed to perform specific tasks

- With its GPIO (General Purpose Input/Output) pins, Raspberry Pi can interact with external components

- It has built-in Wi-Fi and Bluetooth capabilities, making it easy to connect to other devices

- Raspberry Pi is widely used in the field of electronics and robotics

Choosing the right components for your automatic garbage disposal system

When it comes to building an automatic garbage disposal system using Raspberry Pi, selecting the right components is crucial. The components you choose will determine the efficiency and functionality of your system.

First and foremost, you will need a Raspberry Pi board. This small, affordable computer is the heart of your system and will be responsible for controlling the disposal process. Make sure to choose a model that suits your needs and budget.

Next, you will need a sensor to detect the presence of garbage. There are various types of sensors available, such as ultrasonic sensors or infrared sensors. Consider the range, accuracy, and reliability of the sensor before making a decision.

In addition, you will need a motor to power the garbage disposal mechanism. Look for a motor that is compatible with your Raspberry Pi board and can provide enough torque to handle the disposal process.

Lastly, don’t forget about the power supply, wiring, and other necessary components to connect everything together. It’s important to ensure that all the components are compatible and work seamlessly with each other.

By carefully selecting the right components, you can ensure the success of your automatic garbage disposal system and create a more efficient and sustainable waste management solution.

Step 1: Setting up the Raspberry Pi for your project

Before you can start building your automatic garbage disposal system using Raspberry Pi, you need to set up the Raspberry Pi itself. This involves a few simple steps to ensure that your device is ready to be programmed and connected to the necessary components.

First, you will need to gather all the necessary materials, including a Raspberry Pi board, a power supply, an SD card, and a keyboard and mouse for initial setup. Once you have these items, you can begin by inserting the SD card into the Raspberry Pi and connecting it to a monitor using an HDMI cable.

Next, you will need to connect the power supply to the Raspberry Pi and turn it on. This will boot up the device and allow you to access the operating system. Follow the on-screen instructions to set up the Raspberry Pi, including selecting your preferred language and connecting to a Wi-Fi network if necessary.

Once the initial setup is complete, you can proceed to the next steps in building your automatic garbage disposal system. It is important to ensure that your Raspberry Pi is properly set up and functioning before moving forward, as this will be the central control unit for your project.

Step 2: Building the physical structure of the garbage disposal system

- Start by gathering all the necessary materials and tools for building the physical structure of your automatic garbage disposal system.

- Design a suitable enclosure or housing for the Raspberry Pi and other components, ensuring that it is sturdy and can withstand the disposal process.

- Consider using a waterproof and durable material for the enclosure to protect the Raspberry Pi from any potential damage caused by moisture or other environmental factors.

- Install the necessary sensors and actuators in the enclosure, such as proximity sensors to detect the presence of garbage and a motor to control the disposal mechanism.

- Ensure that all the components are securely mounted and properly connected to the Raspberry Pi.

- Test the physical structure to ensure that it is stable and can withstand the movements and vibrations during the disposal process.

Step 3: Programming the Raspberry Pi to control the disposal process

Once you have set up the Raspberry Pi and built the physical structure of your garbage disposal system, it’s time to program the Raspberry Pi to control the disposal process. Here are the steps to follow:

- Install the necessary software: Begin by installing the operating system on your Raspberry Pi. You can choose from various options such as Raspbian, Ubuntu, or Windows IoT Core.

- Learn Python programming: Python is the recommended programming language for Raspberry Pi. Familiarize yourself with the basics of Python programming to effectively control the disposal process.

- Write the code: Start by writing the code that will control the motor of the garbage disposal system. You will need to use the GPIO (General Purpose Input/Output) pins of the Raspberry Pi to interface with the motor.

- Implement sensors: If you want to add additional functionality to your garbage disposal system, such as automatic lid opening or detecting when the bin is full, you will need to connect and program sensors to work with the Raspberry Pi.

- Test and debug: Once you have written the code, test it to ensure that the Raspberry Pi is controlling the disposal process correctly. Debug any issues that arise and make necessary adjustments to the code.

Remember to refer to the documentation and resources available for Raspberry Pi programming to help you along the way. With the right programming, your automatic garbage disposal system will be up and running smoothly.

Step 4: Testing and troubleshooting your automatic garbage disposal system

Once you have completed the programming of your Raspberry Pi garbage disposal system, it is important to thoroughly test and troubleshoot it to ensure its proper functionality. Testing will help you identify any potential issues or bugs that may arise during operation.

Start by running a test cycle of the garbage disposal system to see if it operates as intended. Pay close attention to the timing and accuracy of the disposal process. If any errors occur, carefully review your code and make necessary adjustments.

Additionally, check all the physical components of the system to ensure they are properly connected and functioning. Inspect the wiring, sensors, and motors for any signs of damage or loose connections.

If you encounter any problems during testing, consult the Raspberry Pi documentation or online forums for troubleshooting tips. It may also be helpful to seek assistance from experienced Raspberry Pi users or professionals in the field.

Remember, thorough testing and troubleshooting are crucial to ensure the reliability and efficiency of your automatic garbage disposal system.

Enhancing the functionality of your Raspberry Pi garbage disposal system

Now that you have successfully built and programmed your automatic garbage disposal system using Raspberry Pi, it’s time to take it to the next level by enhancing its functionality. There are several ways you can do this:

1. Adding sensors

Consider integrating sensors into your system to detect the level of garbage in the bin. This will allow your Raspberry Pi to automatically trigger the disposal process when the bin is full.

2. Implementing sorting capabilities

With the addition of sensors and actuators, you can program your Raspberry Pi to sort different types of waste into separate compartments. This will enable efficient recycling and waste management.

Incorporating remote control

By connecting your Raspberry Pi to a mobile app or a web interface, you can control and monitor your garbage disposal system from anywhere. This adds convenience and flexibility to the system.

By enhancing the functionality of your Raspberry Pi garbage disposal system, you can create a more efficient and sustainable waste management solution. Embrace innovation and continue exploring the possibilities of Raspberry Pi technology in waste management.

The future of waste management with Raspberry Pi technology

The integration of Raspberry Pi technology in waste management systems has the potential to revolutionize the way we handle and dispose of garbage. With its capabilities for automation and control, Raspberry Pi can offer a more efficient and sustainable solution for waste management.

One of the key advantages of using Raspberry Pi in waste management is its ability to collect and analyze data. By installing sensors and cameras in garbage bins, Raspberry Pi can monitor the fill level and detect any abnormalities or issues. This data can then be used to optimize waste collection routes, reduce fuel consumption, and minimize the environmental impact.

Raspberry Pi can also enable real-time monitoring and remote control of garbage disposal systems. This means that waste management companies can remotely monitor the status of their systems, detect any malfunctions, and take immediate action to resolve them. This not only improves the efficiency of waste management operations but also reduces the need for manual intervention and maintenance.

Furthermore, Raspberry Pi technology can be integrated with other smart city initiatives, such as energy management and traffic control, to create a more interconnected and sustainable urban environment. By leveraging the power of IoT and data analytics, waste management systems can become more intelligent and adaptive, leading to significant cost savings and environmental benefits.

In conclusion, the future of waste management lies in the adoption of Raspberry Pi technology. Its capabilities for automation, data analysis, and remote control can transform the way we handle and dispose of garbage, making our cities cleaner, greener, and more sustainable.

Embracing innovation for a more efficient and sustainable waste management solution

By utilizing the capabilities of Raspberry Pi, we can create an automatic garbage disposal system that revolutionizes waste management. This technology offers numerous benefits, including increased efficiency and sustainability.

Understanding the basics of Raspberry Pi and selecting the right components are crucial steps in building this system. Setting up the Raspberry Pi and constructing the physical structure are also important considerations.

Programming the Raspberry Pi to control the disposal process is a key aspect of this project. Through testing and troubleshooting, we can ensure that the system functions properly.

Furthermore, we can enhance the functionality of the garbage disposal system by exploring additional features and improvements.

With the potential for future advancements in waste management, Raspberry Pi technology holds great promise. By embracing innovation, we can create a more efficient and sustainable solution for waste disposal.

Frequently Asked Questions

Q: What are the benefits of an automatic garbage disposal system using Raspberry Pi?

A: An automatic garbage disposal system using Raspberry Pi offers several benefits, including increased convenience, improved efficiency, and reduced manual labor. It allows for hands-free operation and can be programmed to dispose of waste at specific times, making waste management more efficient and sustainable.

Q: What is Raspberry Pi and what are its capabilities?

A: Raspberry Pi is a small, affordable computer that can be used for various projects and applications. It is capable of running a full operating system and can be programmed to perform a wide range of tasks. With its GPIO (General Purpose Input/Output) pins, it can interface with external components and devices, making it suitable for building automated systems like a garbage disposal system.

Q: How do I choose the right components for my automatic garbage disposal system?

A: To choose the right components for your automatic garbage disposal system, you need to consider factors such as the size and capacity of the garbage bin, the type of motor or actuator required for the disposal mechanism, and the sensors needed for detecting waste levels or controlling the disposal process. It is important to research and select components that are compatible with Raspberry Pi and meet your specific requirements.

Q: How do I set up the Raspberry Pi for my garbage disposal project?

A: To set up the Raspberry Pi for your garbage disposal project, you will need to install the operating system (such as Raspbian) on an SD card and connect it to the Raspberry Pi. You will also need to connect the necessary peripherals, such as a monitor, keyboard, and mouse. Once the initial setup is complete, you can proceed with configuring the software and programming the Raspberry Pi for controlling the disposal system.

Q: How do I build the physical structure of the garbage disposal system?

A: Building the physical structure of the garbage disposal system involves designing and constructing a container or bin for holding the waste, as well as the mechanism for disposing of the waste. This may include components such as a motor, gears, and a chute or opening for waste disposal. It is important to ensure that the structure is sturdy, safe, and properly aligned with the Raspberry Pi for seamless operation.

Q: How do I program the Raspberry Pi to control the disposal process?

A: Programming the Raspberry Pi to control the disposal process involves writing code that utilizes the GPIO pins to interface with the components of the garbage disposal system. This code can be written in programming languages such as Python or C/C++. You will need to define the logic for waste detection, disposal timing, and any additional functionalities you want to incorporate. Resources such as online tutorials and documentation can help you learn the necessary programming techniques.

Q: How do I test and troubleshoot my automatic garbage disposal system?

A: Testing your automatic garbage disposal system involves running various scenarios to ensure that it functions as intended. This includes checking if the waste detection sensors are working properly, the disposal mechanism operates smoothly, and the Raspberry Pi executes the programmed instructions correctly. If any issues arise, troubleshooting techniques such as checking connections, reviewing the code, and using debugging tools can help identify and resolve the problems.

About The Author

Zeph Grant is a music fanatic. He loves all types of genres and can often be found discussing the latest album releases with friends. Zeph is also a hardcore content creator, always working on new projects in his spare time. He's an amateur food nerd, and loves knowing all sorts of random facts about food. When it comes to coffee, he's something of an expert - he knows all the best places to get a good cup of joe in town.