Last Updated on September 17, 2022

In this article, we’ll discuss the most effective methods of deburring plastic components. We’ll discuss what deburring tools are available, how to deburr plastic parts, and whether deburring is a complex process. This article will also answer a question that many of us have: is deburring difficult? And we’ll address some common questions that come up in this process. In the meantime, let’s take a closer look at each of these methods.

How do you remove burrs from plastic?

After machining or molding, unwanted material may be left on a part, which is called a burr. These burrs can take several forms, including roll-over, tear, flag, or poisson. To remove these burrs, you should consider the dimensional tolerance of the plastic part, as well as the risk of cross contamination and grit entrapment. Here are three common methods of burr removal:

Burrs and flash are two types of mechanical defects that can affect product quality and cost. Burrs can be formed in many ways, but the most common is machining operations. A burr will appear as a raised edge that is caused by a sharp edge, a hammer striking a surface, or a piece of fine wire. While burrs can be difficult to remove, they can often be removed with a little elbow grease.

Which tool is used for deburring?

The process of cryogenic deburring removes burrs from machined Delrin(r) parts. This engineered plastic, made by DuPont, combines high strength with low friction and wear resistance. Delrin can be prone to surface irregularities, which can affect the part’s alignment or cause injury to the operator. To minimize these risks, cryogenic deburring is an effective alternative to traditional hand trimming.

Plastic deburring tools are useful for many applications, from small prototypes to large-scale productions. Plastic doll companies, for instance, use deburring tools to ensure flawless final products. However, they’re also becoming more popular for smaller-scale productions, especially prototypes. These tools are necessary for smoother results and sharper edges. Depending on the material used, there are different types of deburring tools.

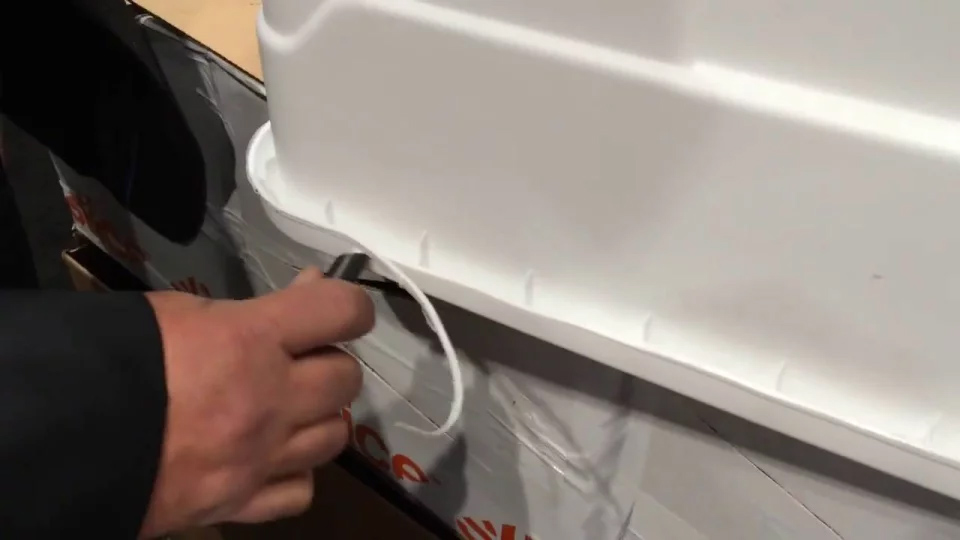

Countersink deburring tools are speciality deburring tools. They are used to remove burrs from plastic pipes and drilled holes. They use a countersink bit mounted into a handle. While they’re commonly affordable and easy to use, they’re limited in what type of burrs they remove. However, the cost of countersink deburring tools is comparable to other methods.

How do you do deburring?

If you’re converting a Delrin block from an industrial grade to a medical grade, you’re probably wondering: How do you deburr Delrin parts? You can use various tools, but a spinning brush is the most effective method. This method removes residual Delrin hair and is inexpensive. You can also use a heat gun and low scratch tube brush dipped in a water-based slurry.

Plastic machining is a great alternative to metal because of its lightweight, corrosion-resistant properties. However, plastic parts still require specialized tooling, precise dimensional tolerances, and surface finishes. In order to eliminate machine burrs while maintaining part integrity, proper deburring is required. There are several methods available. Learn which one will work best for your specific parts and machine shop. There are several factors to consider when determining how to deburr Delrin.

Is deburring hard?

Is deburring Delrin hard and time consuming? Yes. However, if you’re a manufacturer of machined Delrin parts, there are many benefits to cryogenic deburring. This process uses nitrogen-freeze, a high-pressure gas that eliminates burrs on machined Delrin parts. Cryogenic deburring also produces burr-free teeth and holes, and eliminates the need for labor-intensive manual processes.

A combination of manual and automated methods is often used for deburring plastic components. The manual method is preferred by manufacturers, since it gives them more control over the process. A machine that uses an automated process may not remove internal burrs. In addition, there are different burr sizes, shapes, and lengths, which make it challenging to get rid of all burrs. There are three types of deburring methods specifically designed to remove burrs on plastic components:

Manual deburring is the most traditional method. It requires a skilled machinist and low-cost deburring tools. It’s also highly flexible, but can put a lot of stress on the materials used. It can also be used to deburr metal components. Mechanical deburring is a process where a tool sands or grinds off a component’s burr. This method is best used for metal parts that don’t have a smooth surface.

How do you deburr metal by hand?

There are several methods that can be used to deburr Delrin metal. You can use a hand tool or purchase a deburring machine. Hand deburring is relatively inexpensive and time-consuming, but it does have its drawbacks. For example, most manufacturers will not use Delrin or Nylon, as residual burrs are not as effective in removing the material’s surface defects.

Hand deburring is usually done manually, using a deburring tool held against the part. These tools come in a variety of configurations. These tools can range from blades to countersinks and even brushes. Most of them are designed for quick hole deburring. You can use heavy-duty blades for deep holes and light-duty blades for cross-hole deburring.

A burr is an unwanted piece of material that is left behind when machining a plastic or metal object. This material can be a problem, since it has high water content. Fortunately, there are hand-deburring techniques that can help you remove the burrs from Delrin. These techniques will help you get your workpiece back to perfect shape quickly, and without a lot of waste.

What is the process of removing rough edges or bur

Deburring involves the removal of rough edges or burs from metal parts, such as gears, bearings, and valves. Metal burrs often interfere with other finishing processes and cause costly issues for manufacturers. In addition, deburring removes the surface coating of metal parts, resulting in smoother, burr-free teeth and holes. The process of deburring a Delrin gear requires only minimal preparation.

Delrin parts can be deburred with either hand trimming or cryogenic deburring. Hand trimming requires workers to deburr parts one at a time. Cryogenic deburring, on the other hand, produces consistent results across thousands of machined Delrin parts. Cryogenic deburring is a batch process that removes burrs from machined Delrin parts.

Can you deburr plastic?

In some cases, you may be wondering: “Can you deburr Delrin plastic?” Certainly, you can, but there are some key issues with this type of plastic. For one thing, it is very labor-intensive and inefficient. In addition, hand deburring can result in repetitive motion injuries and is often ineffective. Secondly, you risk damaging the plastic part because residual burrs often result in more flash and inconsistency. Therefore, it is important to find a deburring machine that can ensure your parts are completely defect-free.

There are many ways to deburr Delrin plastic. First, you need to find out how the material is made. There are three types of deburring processes. There are mechanical, manual, and cryogenic. Mechanical deburring uses grinding wheels or other abrasive media to remove burrs from plastic components. Manual deburring is an effective option for most applications. The advantages of manual deburring include low cost and increased flexibility. Furthermore, the process does not disturb the material’s dimensional tolerance.

What causes burrs how can they be reduced or elimi

Cryogenic deburring is one method for removing burrs from Delrin(r) parts. Delrin is a composite material produced by DuPont that combines high strength, low friction, and excellent wear resistance. Burrs are often created during the machining process and can cause the part to misalign, fail, or cause injury to the operator. Fortunately, cryogenic deburring is an easy way to eliminate or reduce them.

When using conventional cutting techniques, it’s important to be careful not to change the dimensional tolerances of the parts. Cutting Delrin with a traditional cutter can cause burrs. If you do, you may introduce fibrous artifacts. A sharper cutter is recommended. You should also use climb milling and conventional cutting techniques. Traditional methods, such as hand deburring, can also introduce cross contamination.

About The Author

Wendy Lee is a pop culture ninja who knows all the latest trends and gossip. She's also an animal lover, and will be friends with any creature that crosses her path. Wendy is an expert writer and can tackle any subject with ease. But most of all, she loves to travel - and she's not afraid to evangelize about it to anyone who'll listen! Wendy enjoys all kinds of Asian food and cultures, and she considers herself a bit of a ninja when it comes to eating spicy foods.