Last Updated on July 27, 2023

Welcome to our article on understanding the concept of limiting speed in bearings. In this guide, we will explore the factors that affect the limiting speed of bearings and provide a step-by-step guide to calculating this crucial parameter. Determining the dynamic load rating of the bearing and calculating the equivalent dynamic bearing load are essential steps in this process. Additionally, we will discuss the importance of considering lubrication conditions, viscosity of the lubricant, bearing’s internal clearance and preload, cage design and material, as well as the operating temperature and environmental conditions. By accurately calculating the limiting speed, you can ensure optimal performance of your bearings. Let’s dive in!

Factors Affecting the Limiting Speed of Bearings

When it comes to calculating the limiting speed of bearings, there are several factors that need to be taken into consideration. These factors can greatly impact the performance and durability of the bearings. Here are some key factors to consider:

- Bearing Type: Different types of bearings have different limiting speeds. For example, deep groove ball bearings have higher limiting speeds compared to cylindrical roller bearings.

- Bearing Size: The size of the bearing also plays a role in determining its limiting speed. Generally, smaller bearings have higher limiting speeds.

- Load: The load on the bearing can affect its limiting speed. Higher loads can reduce the limiting speed, while lighter loads can increase it.

- Lubrication: Proper lubrication is crucial for optimal bearing performance. The type and viscosity of the lubricant can impact the limiting speed.

- Temperature: High temperatures can reduce the limiting speed of bearings. It is important to consider the operating temperature and choose bearings that can withstand the required temperature range.

By considering these factors and following the step-by-step guide to calculating the limiting speed, you can ensure optimal performance and longevity of your bearings.

Step-by-step guide to calculating the limiting speed of bearings

Calculating the limiting speed of bearings is a crucial step in ensuring optimal performance and longevity of the bearing. It involves considering various factors and performing a series of calculations. Here is a step-by-step guide to help you calculate the limiting speed:

1. Determining the dynamic load rating of the bearing: The dynamic load rating indicates the maximum load that a bearing can withstand without experiencing excessive wear or damage. It is typically provided by the bearing manufacturer.

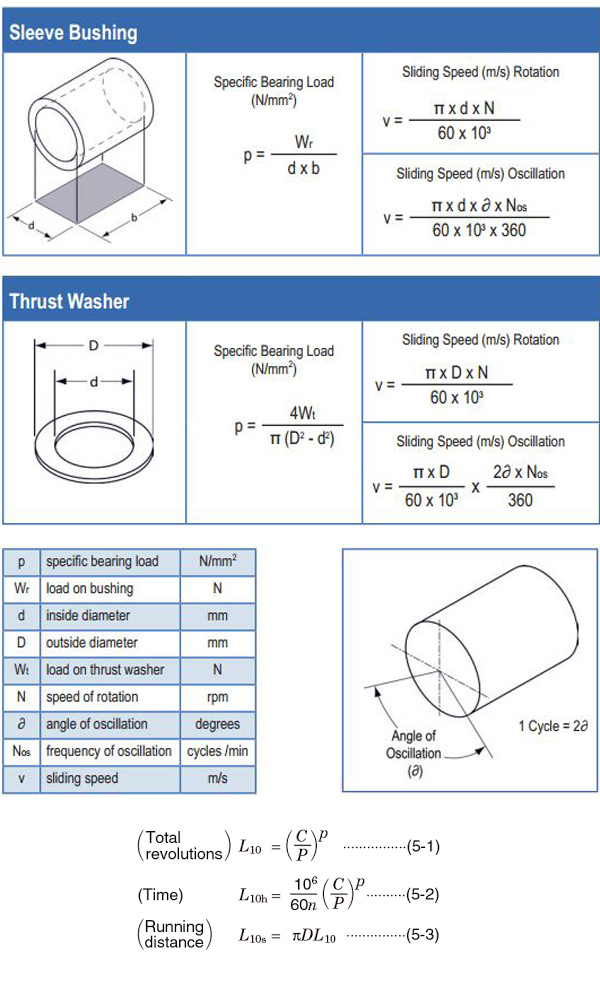

2. Calculating the equivalent dynamic bearing load: The equivalent dynamic bearing load takes into account the combined effect of radial and axial loads on the bearing. It is calculated using specific formulas provided by bearing manufacturers.

3. Considering the lubrication conditions and viscosity of the lubricant: Proper lubrication is essential for reducing friction and heat generation in bearings. The viscosity of the lubricant plays a crucial role in determining the limiting speed.

4. Accounting for the bearing’s internal clearance and preload: Internal clearance refers to the space between the rolling elements and the raceways. Preload is the force applied to eliminate any clearance. Both factors affect the limiting speed.

5. Evaluating the bearing’s cage design and material: The cage holds the rolling elements in place and affects their movement. The design and material of the cage can impact the limiting speed.

6. Taking into account the operating temperature and environmental conditions: High temperatures and harsh environmental conditions can affect the performance of bearings. Considering these factors is crucial in calculating the limiting speed.

By following these steps and considering all the relevant factors, you can accurately calculate the limiting speed of bearings and ensure optimal performance in various applications.

Determining the dynamic load rating of the bearing

One of the key factors in calculating the limiting speed of a bearing is determining its dynamic load rating. The dynamic load rating is a measure of the maximum load that a bearing can withstand without experiencing excessive wear or failure. It is typically provided by the bearing manufacturer and is expressed in terms of the load that will cause a specific amount of permanent deformation in the bearing material.

To determine the dynamic load rating, you will need to consider factors such as the type of bearing, its size, and the material it is made of. You can usually find this information in the bearing manufacturer’s catalog or technical specifications.

Once you have determined the dynamic load rating, you can use it as a reference point for calculating the limiting speed of the bearing. This will help you ensure that the bearing is operating within its safe operating limits and will help prevent premature failure or damage.

4. Determining the dynamic load rating of the bearing

Before calculating the limiting speed of a bearing, it is important to determine the dynamic load rating of the bearing. The dynamic load rating is the maximum load that a bearing can withstand without experiencing excessive wear or damage. This rating is typically provided by the bearing manufacturer and is expressed in terms of the load that will cause a specific amount of permanent deformation in the bearing.

To determine the dynamic load rating, you will need to consider factors such as the type of bearing, the size of the bearing, and the material from which the bearing is made. It is important to note that the dynamic load rating is based on a specific set of operating conditions, including speed, temperature, and lubrication.

Once you have determined the dynamic load rating of the bearing, you can proceed to calculate the limiting speed.

6. Considering the lubrication conditions and viscosity of the lubricant

When calculating the limiting speed of a bearing, it is crucial to take into account the lubrication conditions and the viscosity of the lubricant being used. Proper lubrication is essential for reducing friction and heat generation, which can significantly affect the bearing’s performance and limiting speed.

Here are some key points to consider:

- Choose the right lubricant: Different types of bearings require different types of lubricants. It is important to select a lubricant that is suitable for the specific bearing and its operating conditions.

- Consider the lubrication method: The method of lubrication can also impact the limiting speed of the bearing. Common methods include oil bath, oil mist, grease, and oil jet lubrication.

- Check the lubricant viscosity: The viscosity of the lubricant plays a crucial role in determining the limiting speed. Higher viscosity lubricants tend to create more resistance, while lower viscosity lubricants may not provide sufficient lubrication.

- Monitor lubricant contamination: Contaminants such as dirt, dust, and moisture can degrade the lubricant’s performance and increase friction. Regularly inspect and clean the lubrication system to ensure optimal lubricant quality.

By considering these factors and ensuring proper lubrication, you can enhance the performance and extend the limiting speed of your bearings.

Accounting for the bearing’s internal clearance and preload

When calculating the limiting speed of a bearing, it is crucial to take into account the bearing’s internal clearance and preload. Internal clearance refers to the amount of internal space within the bearing, while preload refers to the force applied to the bearing to eliminate any internal clearance.

The internal clearance and preload of a bearing can significantly affect its limiting speed. If the internal clearance is too large, it can result in excessive vibration and heat generation, leading to premature bearing failure. On the other hand, if the preload is too high, it can cause excessive friction and heat, also reducing the bearing’s limiting speed.

To accurately calculate the limiting speed, it is essential to determine the appropriate internal clearance and preload for the specific application. This can be done by considering factors such as the desired operating temperature, load conditions, and the type of bearing being used.

By accounting for the bearing’s internal clearance and preload, engineers can ensure that the bearing operates within its specified limits, maximizing its performance and longevity.

Evaluating the bearing’s cage design and material

Another important factor to consider when calculating the limiting speed of a bearing is the design and material of the bearing’s cage. The cage, also known as the retainer, is responsible for holding the rolling elements in place and maintaining their proper spacing.

The design of the cage can have a significant impact on the limiting speed of the bearing. A well-designed cage will minimize friction and allow for smooth movement of the rolling elements, resulting in higher speeds. On the other hand, a poorly designed cage can cause excessive friction and heat generation, limiting the speed at which the bearing can operate.

The material of the cage is also important. It should be strong enough to withstand the forces exerted on it during operation, while also being lightweight to minimize inertia. Common materials used for bearing cages include steel, brass, and synthetic materials such as nylon.

When calculating the limiting speed of a bearing, it is crucial to evaluate the design and material of the cage to ensure optimal performance and longevity of the bearing.

Heading 9: Taking into account the operating temperature and environmental conditions

When calculating the limiting speed of a bearing, it is crucial to consider the operating temperature and environmental conditions in which the bearing will be used. These factors can greatly impact the performance and lifespan of the bearing.

Operating temperature plays a significant role in determining the limiting speed of a bearing. High temperatures can cause the lubricant to degrade, leading to increased friction and wear. On the other hand, extremely low temperatures can cause the lubricant to thicken, resulting in poor lubrication. It is important to select a bearing that can withstand the anticipated operating temperature range to ensure optimal performance.

Environmental conditions such as dust, moisture, and corrosive substances can also affect the limiting speed of a bearing. Dust and moisture can contaminate the lubricant and cause abrasive wear, while corrosive substances can lead to chemical damage. It is essential to choose a bearing that is designed to withstand the specific environmental conditions in which it will be used.

By taking into account the operating temperature and environmental conditions, engineers and designers can accurately calculate the limiting speed of a bearing and select the most suitable bearing for the application. This ensures optimal performance and extends the lifespan of the bearing.

Importance of accurately calculating the limiting speed for optimal bearing performance

Calculating the limiting speed of a bearing is crucial for ensuring optimal performance and longevity. Accurate calculation of the limiting speed allows engineers and technicians to determine the maximum rotational speed at which a bearing can operate without experiencing excessive heat generation, vibration, or premature failure.

By accurately calculating the limiting speed, engineers can select the appropriate bearing for a specific application, taking into consideration factors such as load, lubrication, and operating conditions. This ensures that the bearing can withstand the demands of the application and operate efficiently.

Furthermore, accurate calculation of the limiting speed helps in identifying potential issues or limitations that may arise during operation. It allows for proactive measures to be taken, such as adjusting the operating conditions or selecting a different bearing design, to prevent any performance issues or failures.

In conclusion, accurately calculating the limiting speed is essential for achieving optimal bearing performance and reliability. It enables engineers to make informed decisions and select the most suitable bearing for a given application, ultimately ensuring smooth and efficient operation.

Learn how to calculate the limiting speed of bearings for optimal performance. Factors, steps, and considerations explained.

About The Author

Orochi Konya is a student of the web. He has been dabbling in it since he was young, and has become an expert in his own right. He loves all things digital, from making websites to programming to social media. In his spare time, Orochi enjoys indulging in his other passion: music. He loves listening to all kinds of music and often spends hours creating playlists on Spotify. He also enjoys drawing manga and watching anime in his free time. Orochi is a friendly pop-culture guru who is always happy to chat about the latest trends in both Japan and the U.S.